Product Description

Advantages:

The process is mature and investment is low, which is suitable for coating modification of stearic acid. Self-friction heat generation, less accessory equipment;

It is suitable for the modification of 325 ~ 1250 mesh powder.

Disadvantages:

Low air volume, dispersion was weak, especially fine powder, with more modifier dosage;

Self-friction heat generation is easy to be affected by environmental factors, and hard to control the modification temperature ;

There is dead zone and low coating rate.

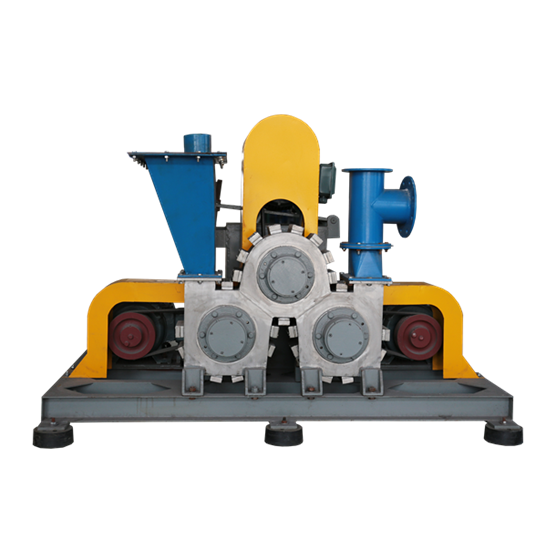

Principle and characteristics: the relative motion of three rotors can change the effect of cyclone and eddy current to realize the coating of powder surface. Without heating device, it has the advantages of low investment and low operation cost.

Power range: 11kW ~ 225kW

Maximum capacity: 6t/h

Technical parameter

|

Model |

SG200 |

SG3/300 |

SG3/600 |

SG3/900 |

|

Size (D97:10μm) |

150kg/h |

1.5t/h |

3t/h |

6t/h |

|

Power |

11kW |

55.5kW |

111kW |

225kW |

Main specification

| Model |

Main Power (kw) |

Blower Power (kw) |

Speed of Shaft (r.p.m) |

Capacity (kg/h) |

Weight (t) |

Overall Dimension (L*W*H)mm |

| CLG-200D |

11 |

2.2 |

4600 |

40-150 |

1 |

3200*600*2200 |

| CLG-3/300 |

3-18.5 |

5.5 |

4500 |

500-1800 |

3 |

5800*1800*5600 |

| CLG-3/600 |

3-37 |

15-22 |

2700 |

2000-4000 |

10 |

11200*3100*6200 |

| CLG-3/900 |

3-75 |

45 |

1800 |

4000-7000 |

20 |

21000*3800*6500 |

| NOTE: Capacity is according to medium hard limestone.The size,humidity level and characters of materical swill influence the capacity. |

Advantages:

The process is mature and investment is low, which is suitable for coating modification of stearic acid. Self-friction heat generation, less accessory equipment;

It is suitable for the modification of 325 ~ 1250 mesh powder.

Disadvantages:

Low air volume, dispersion was weak, especially fine powder, with more modifier dosage;

Self-friction heat generation is easy to be affected by environmental factors, and hard to control the modification temperature ;

There is dead zone and low coating rate.

Advantages:

The process is mature and investment is low, which is suitable for coating modification of stearic acid. Self-friction heat generation, less accessory equipment;

It is suitable for the modification of 325 ~ 1250 mesh powder.

Disadvantages:

Low air volume, dispersion was weak, especially fine powder, with more modifier dosage;

Self-friction heat generation is easy to be affected by environmental factors, and hard to control the modification temperature ;

There is dead zone and low coating rate.